flow rate calculator 3d printer

On the other hand the flow rate is the volumetric measure of material extruded from the nozzle. If you push your printer above that limit you will get underextrusion as well as poor layer adhesion.

The formula is.

. Flow Rate Calculator- Introduction. How to do the Flow Rate Calibration. Divide 186 by 4 to get the average which.

Naturally for many instances this is either too much or on the odd occasion too little. Modify the flow rate to 90. Calculate the maximum flow rate.

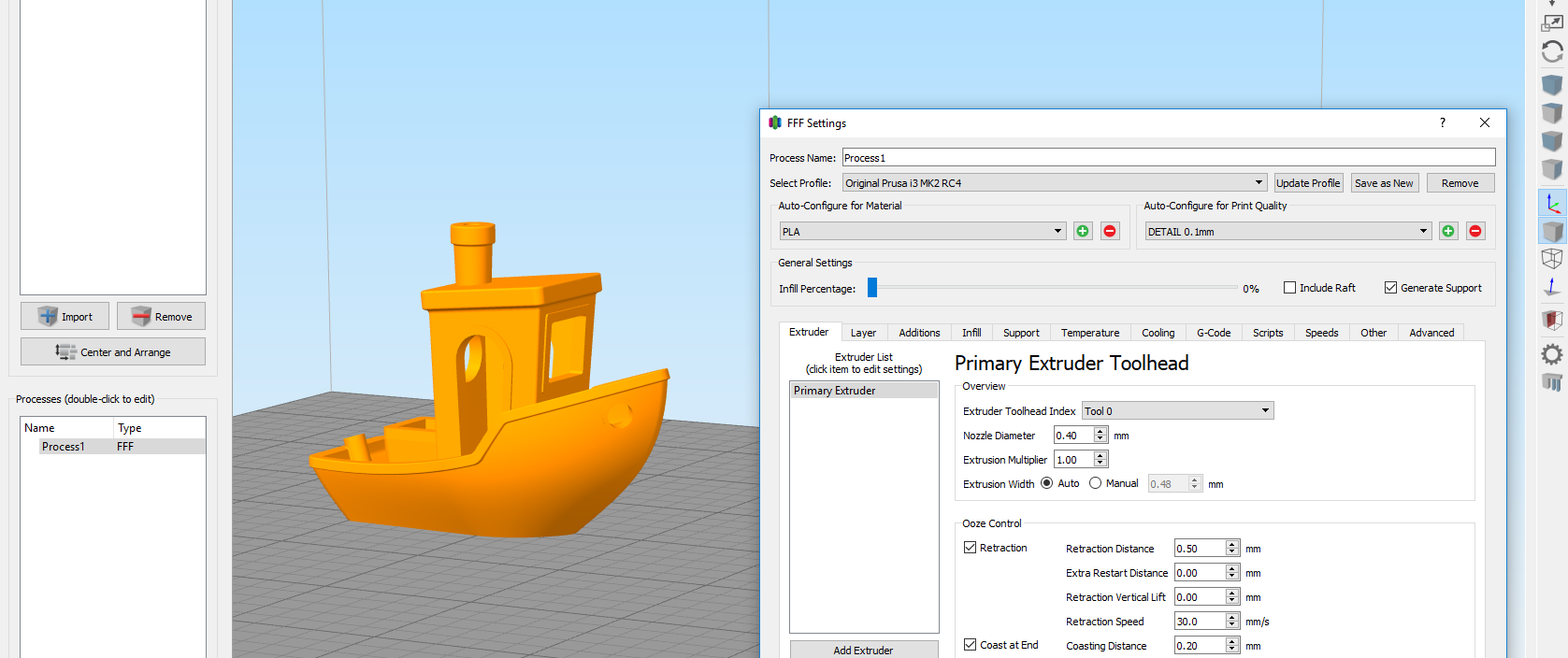

With a 04mm nozzle and a flow rate of 1 or 100 the thickness of a single wall should be 04mm. Flow Rate Calculator- Introduction. It aims to make calibrating your 3D printer as easy as possible.

For example if you measured 044 047 049 and 046 you would add that up to equal 186. Extrussions speed is F600 then divide the 600 by 60 to get the speed mm this would be 10 mm second here. Before we start the flow rate calibration we need to make sure the filament size value is correctly set in your slicer of choice.

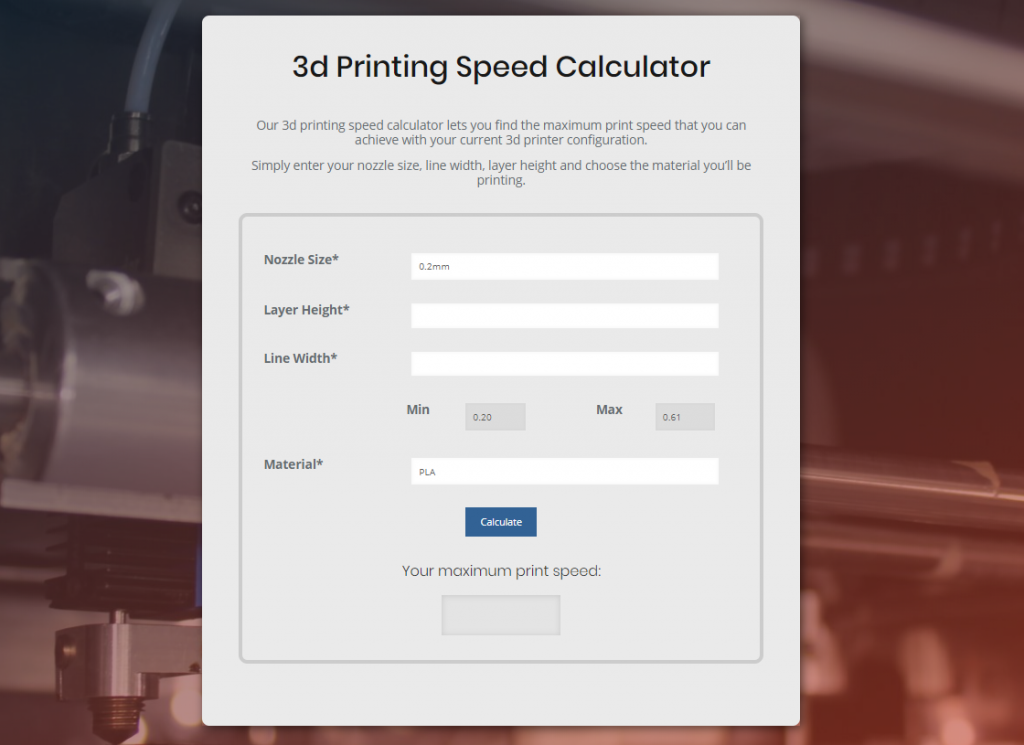

Every hotend and extruder combination has a capacity to melt and deposit a certain volume of filament every second. Simply enter your nozzle size line width layer height and choose the material youll be printing. Max flow rate Max extrusions speed pi filament diameter 2 2.

So using this tool I can put in what Im planning to do then see whether its likely to be too much. Our 3d printing speed calculator lets you find the maximum print speed that you can achieve with your current 3d printer configuration. New Micro Step Rate.

3D printer calibration site V2 - Still free and better than ever. Every hotend and extruder combination has a capacity to melt and deposit a certain volume of filament every second. Calibrating the flow rate will involve printing a test cube and measuring its walls to identify the actual flow rate compared to the flow rate value.

Modify your existing slicers settings to match the list below. The Maximum volumetric speed setting MVS in PrusaSlicer is one of the most powerful features of this slicer yet it is poorly documented and not well understood. 3D printer calibration revolutionised - Step by step to better print quality.

If the walls are thinner than 04mm the flow rate needs to be increased. Maximum volumetric speed in PrusaSlicer. You can check you slicer parameters using this calculator to make sure you avoid this limit.

3D feed and flow rates remain some of the most confused and inter-used terms in 3D printing circles. New Steps Per mm. If you push your printer above that limit you will get underextrusion as well as poor layer adhesion.

Obtained the new flow rate 90 only remains to modify the parameter in the 3D lamination software that is used in our case the Cura 3D. The feed rate is the printhead travel speed along the X-Y plane. π a2 b2.

Divide the maximum flow rate obtained in step 6 by the surface area of your normal print line obtained in step 7. Alternatively please have a look at our affiliate links in the 3D Printing Deals and Coupons section. 3D Printer Feed Rate vs Flow Rate.

Flow rate is a multiplier denoted in percentages that determines the amount of plastic the printer extrudes at any given moment. As you can see despite sounding similar flow rate and. Measure the Filament Diameter.

This value is a safe max printing speed for your 3D printer with the nozzle diameter temperature and filament you previously set. Thus the need for calibrating the filament flow rate. Consequentially dimensional accuracy and line widths all go out of the window as there is no benchmark to calculate from.

Hence by default 3D printing slicers set the flow rate to 10 or 100. Current Micro Steps Rate. In theory the Ender 3 and E3D V6 both have 60W heaters so you might expect to also be able to do 17 mm3s but you have a weaker bowden extruder.

Lets assume that the max. New flow rate 04 average wall width 100. This is typical for most printers as purchased.

Lets assume that the max. This page serves as a companion for this video. Calculate the new flow rate using this formula.

If you find our articles helpful and would like to help support the Make N Print website please visit the support us page for more information. Formula to calculate the necessary flow for any material. This same calculation is used regardless of the axis.

If we know the maximum flow rate of the hot end we can use this formula. Lets assume that we have a maximum flow rate of 1386 mm³ and we want to print with a layer height of 02 mm and a layer width of 048 mm. On the other hand the feed rate is a multiplier denoted in percentages the printer uses to calculate the movement speed for all axes including the E axis.

Now we can use this formula. Extrussions speed is F600 then divide the 600 by 60 to get the speed mm this would be 10 mm second here. Recommended maximum speed maximum flow rate layer height extrusion width to calculate the maximum printing speed.

You can check you slicer parameters using this calculator to make sure you avoid this limit. The MVS setting essentially imposes a governor on the maximum amount of filament that the slicer will attempt to push through your 3D printers. In this post we will learn about calibration of material flow rate in the 3D printers.

And re-print the cube to verify that the measurements obtained with the new flow rate are correct. It has received a major update to bring it up to V2 which is explained in this video. Download our test file and import it in your slicer.

Flow rate calibration is extremely simple and can be completed in less than 30 minutes using the process below. The most common filament used in 3D printing has a thickness of 175 mm with small variations caused by the manufacturing process.

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print

How To Calibrate Your Extruder E Steps Flow Rate Perfectly 3d Printerly

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print

The Ashrae Duct Size Calculator Showing How To Find The Duct Size For A Given Friction Rate And Air Flow Rate Duct Friction Flex Duct

Calculating Iv Drips Rates Pharmacology Nursing Nursing School Survival Paramedic School

Online Calculator For Metal 3d Printing 2021 03 12 Industrial Heating

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Section 1 8 Esteps And Flow Rate Youtube

Mortgage Refinance Mortgagelawyer Mortgage Refinance Mortgagetools Mortgage Refinance Mortgage Mortgage Refinance Calculator Home Equity Loan Calculator

3d Print Speed How To Find The Optimal Speed For Reliable And Constant Print Quality

3d Print Speed How To Find The Optimal Speed For Reliable And Constant Print Quality

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print